SAP production planning

One of the modules offered by SAP (Systems, Applications, and Products in Data Processing) to assist business processes is SAP Production Planning (SAP PP). A comprehensive tool for managing and streamlining production processes, SAP PP is intended for use by enterprises.

Master data: This comprises information on the goods, supplies, and labor used throughout production. Production order planning and execution require master data.

The bill of materials, or BOM, is a list of the parts and raw materials needed to make a product. It outlines a product’s hierarchical structure.

Work Centers: Work centers are the actual or hypothetical places where manufacturing processes are carried out. They contain data regarding availability, capacity, and scheduling.

Routing: Routings specify the order in which tasks are to be completed in a work center. The production steps and their sequential execution order are specified.

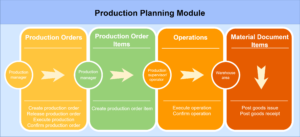

Production scheduling, capacity planning, and material needs planning (MRP) are all part of the process of developing and overseeing production plans. MRP makes sure that the proper supplies are available when they’re needed.

Production Orders: The production plan is carried out through the use of production orders. They include details about what, where, and when to produce it together with the necessary resources.

Planning for Capacity: Planning for capacity entails determining a work center’s ability to produce enough goods to meet demand. It aids in preventing resource overuse or underuse.

Shop Floor Control: This refers to keeping an eye on and managing the shop floor production process. It covers tasks including reporting, confirming, and releasing orders.

Material Requirements Planning (MRP): MRP is an essential tool that determines, from the production plan, the necessary materials for production, guaranteeing that the appropriate resources are accessible when needed.

Integration with other SAP Modules: In order to offer complete supply chain visibility and control, SAP PP is tightly connected with other SAP modules, including SAP Materials Management (MM), SAP Sales and Distribution (SD), and SAP Quality Management (QM).

Organizations can increase productivity, save costs, streamline production processes, and improve overall business performance by implementing SAP Production Planning. By offering real-time insights into production activity and resource utilization, it facilitates improved decision-making.