SAP PP

The acronym for SAP Production Planning is SAP PP. It is a module that addresses many facets of production planning and control within the SAP ERP (Enterprise Resource Planning) system. Demand forecasting, material planning, production scheduling, and shop floor execution are just a few of the areas that SAP PP integrates to help organizations plan and carry out manufacturing processes more efficiently.

Important features of SAP PP consist of:

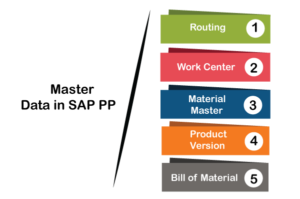

Master Data Management: Production versions, work centers, routings, bills of materials (BOMs), and other master data can be managed using SAP PP.

Planning for Material Requirements (MRP): It assists in determining the amount of material needed based on projected production orders, sales orders, and demand projections. MRP in SAP PP guarantees both the availability of materials and the effective execution of production.

Shop Floor Control: SAP PP offers solutions for controlling order release, confirmation, and goods receipt, among other production activities on the shop floor.

Production Planning Strategies: Businesses can match their production processes to their unique business requirements by using SAP PP’s support for a number of production planning strategies, including make-to-stock, make-to-order, and configure-to-order.

Capacity Planning: This feature aids in production scheduling by taking into account the capacities of work centers and other resources. It guarantees that resources are used as efficiently as possible and that production schedules are realistic.

Shop Floor Control: SAP PP offers solutions for controlling order release, confirmation, and goods receipt, among other production activities on the shop floor.

Production Planning Strategies: Businesses can match their production processes to their unique business requirements by using SAP PP’s support for a number of production planning strategies, including make-to-stock, make-to-order, and configure-to-order.