SAP PP

One of the most important components of SAP’s ERP (Enterprise Resource Planning) package, SAP PP (Production Planning) aids businesses in organizing and managing their production processes. Below is a detailed description of all of its parts and features.

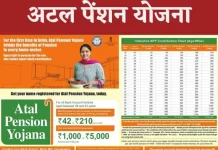

Master Information:

A material master holds data about every material that a business purchases, manufactures, stores, and sells.

A product’s bill of materials (BOM) is an organized inventory of all the parts, subassemblies, and raw materials that go into making it.

Work Center: A designated area within a factory where tasks are completed.

Routing: Specifies the steps that the manufacturing process must take and the order in which they should be completed.

One high-level planning tool that aids in balancing supply and demand is sales and operations planning, or SOP.

Demand management plans requirements and forecasts to make sure there is enough inventory to meet demand without going overboard.

Material Requirements Planning (MRP): Determines the components and materials required for a product’s production.

Apply Link

Job Responsibilities:

Education And Experience

Required Education / Experience

- Bachelor’s Degree or equivalent in Business, IT, Engineering or related field

- 10+ years specifying, configuring, deploying and supporting SAP Production Planning and Quality Management with integrated functionality from other SAP modules, preferably with experience in a global environment

- At least two full cycle implementations of SAP primarily as either a Production Planning or Quality Management specialist

- Proficient in MS Office (particularly MS Excel) and MS SharePoint

Preferred Education / Experience

- SAP Certification in either PP or QM

- 10+ years experience specifying, configuring, deploying and supporting a dedicated SOP software system

- Any additional experience configuring for SAP MM, WM, SD, PS, FI or CO modules

- Manufacturing industry experience

########

- 4 Years of strong SAP Production Planning (PP) experience which include min 2-3 end to end implementations and support projects, experience in Variant configuration is also preferred.

- Should have good experience working with Sales and Production plans, Long term planning, demand management, MRP (material requirements planning) Capacity Planning, Production Orders and KANBAN.

- Should have very good knowledge on the business processes associated with SAP PP for discrete manufacturing environment.

- Configuration and working experience on Make-to-Stock (MTS) and Make-to-Order (MTO) strategies.

- To have worked on various material types including KMAT for variant configuration scenarios, defined Class for required variants with pricing, defined object dependencies (OD) and maintained Super BOM and Super Routing.

- Configure and maintain PP master data in interface with VC, Super BOM, Super routing, and Work centers.

- Should have good working knowledge on Variant configuration.

- Should have extensively worked on capacity planning, material requirements planning, Stock requirement list, production order execution, shop floor controls.

- Extensively worked on ABAP debugging, technical and functional specifications, SAP query.

- The SAP Production Planning Consultant is directly responsible for delivery of SAP Producti+B1on Planning (PP) module functional services.

- Working & configuration knowledge of SAP Quality Management,

- Working Exp on including Master Data, Quality planning, Quality Inspection, Quality Certification, Quality Notification.

- Good conceptual knowledge on S/4 HANA

- Configuration and Operation of Demand Planning (DP), Supply Network Planning (SNP), Demand Planning (DP), Sales and Operations Planning (SOP), Net Requirements Calculation, Detailed Scheduling, Capacity Requirements, Master Data in ECC and APO.

- Maintenance and ability to troubleshoot the Core Interface (CIF) between APO and SAP.

- Excellent Understanding of SAP ECC MM and SD Modules.

Candidates must have worked on s4Hana should have worked on at least one implementation or support project.

The location is DELHI/NCR/CHANDIGARH/DEHRADUN/UP/RANCHI/RAIPUR/CALCUTTA.

Send your resume to mahendragupta@arpaninfrasolution.com, hr@arpaninfrasolution.com

######

Years of Experience

- 5 to 8 years of experience working in SAP PP/QM.

Position Requirements

- Responsible for planning and executing SAP Implementation / Development / Support activities regard to SAP Production Planning and ability to handle Production Planning processes.

- Understand client requirements, provide solutions, functional specifications and configure the system accordingly.

- Ability to create presentation/workshop decks for Blueprint that need to be conveyed and be able to present them to the client.

- Ability to create Process Flows in Microsoft Visio’s for the client’s proposed business processes.

- Ability to create Process Definition Document / Design Document (PDD/BDD) and Business Process Procedure (BPP) for the solutions provided.

- Ability to configure SAP PP and deliver work products / packages conforming to the Client’s Standards & Requirements. Strong configuration hands on experience in SAP PP.

- Integration of the PP module with other SAP modules and with external applications.

- Responsible for planning and executing SAP Implementation / Development / Support activities regard to SAP Quality management.

- Understand client requirements, provide solutions, functional specifications and configure the system accordingly.

- Ability to create presentation/workshop decks for Blueprint that need to be conveyed and be able to present them to the client.

- Ability to create Process Flows in Microsoft Visio’s for the client’s proposed business processes.

- Ability to create Process Definition Document / Design Document (PDD) and Business Process Procedure (BPP) for the solutions provided.

- Ability to configure SAP QM (Quality module) and deliver work products / packages conforming to the Client’s Standards & Requirements.

- Strong configuration hands on experience in Quality module.

- Integration of the QM module with other SAP modules like WM,PP,PM and with external applications like LIMS

- In addition to the above the candidate should have been involved in the following during the life cycle of SAP implementation:

- Project preparation

- Unit Testing, Cycle Testing

- Integration Testing

- User Manual Preparation

- User Support activities

- Exposure to ASAP and other structured implementation methodologies

- Regularly interact with the onsite team/client

- Provide status updates in daily/weekly conference calls

- Maintain cordial relationship with onsite team/client

- In addition to the above the candidate should have been involved in the following during the life cycle of SAP implementation:

- Unit Testing, Cycle Testing

- Integration Testing

- User Manual Preparation

- User Support activities

- Exposure to ASAP and other structured implementation methodologies

- Regularly interact with the onsite team/client

- Provide status updates in daily/weekly conference calls

- Maintain cordial relationship with onsite team/client

- Prepare test scripts and perform testing after upgrade

- 5 to 8 years of SAP PP Functional Domain Experience and should have worked for 5 to 8 years on PP Module of SAP projects. Good understanding of PP processes in ECC 6.0

- Should be able to analyze end to end Production Planning scenarios and be able to provide an optimum solution utilizing processes available in PP.

- Responsible in studying and preparing AS-IS study, gap analysis, Blue-Print and Strong configuration hands on experience in the following PP areas

- Basic Data

- Sales & Operations Planning

- Master Planning

- MRP

- Production Orders & Confirmations

- Process Orders & Confirmations

- Make To Order

- Make To Stock

- Repetitive Manufacturing

- Regularly interact with the onsite team/client. Conduct daily/weekly conference calls. Create presentation deck and present them. Maintain cordial relationship with onsite team/client.

- Should have good written and oral communication skills

- Must be a good team player

- Implementation experience should be in version 4.7 upwards. ECC 6 would be a plus

- Hands on experience in configuring / defining the following in the QM module:

- QM in procurement, Source inspection, Vendor evaluation, Vendor selection

- QM in logistics, incoming, in-process & outgoing

- Certificate of analysis

- Sound knowledge in QM processes

- Quality control, Notification, Test equipment & SPC

- Auditing

- Batch management

- Should have good written and oral communication skills

- Must be a good team player

- Familiarity on the basic business processes with any of the following Functional Areas:

- SAP MM

- SAP SD

- SAP FICO

- Document management system

- Engineering change management

- SAP PP

Nice to Have

- SAP Certification on PP Module

- Worked on other modules like MM and VC along with PP

- ABAP/4 Skills and experience on ABAP Query

- SRM, CRM and BW awareness

- Training / Awareness on Netweaver Components

- Prepare training documentation

- Team Leading Experience would be added advantage.

- SAP Certification on QM/PLM Module

- Used Solution Manager in the implementation

- Worked on integration with other modules like MM, WM, SD, PM, PP

- SAP Certification on QM/PLM Module

- Used Solution Manager in the implementation

- Worked on integration with other modules like MM, WM, SD, PM, PP

Professional and Educational Background

- B Tech, M. Tech, MBA, M.com, B.E, B.A, B.com

Additional Information

- Line of Service: Advisory

- Designation: Senior Associate

- Should be open to work in shift timings

- Should be ready to travel to client location if required

##########

[Job Title]

SAP PP Senior Consultant Role (10 +Years)

[Project Details]:

- S/4 Hana implementation for semiconductor business

[Base Location]:

- Bangalore

[Type]:

- Hybrid( 2 days/ week from Bangalore office)Must be willing to work in any shift: 7:30 AM to 4:30 PM shift or 1:30 PM to 10:30 PM shift (all hours in IST)

[Qualifications]

- Any PG/UG from reputed universities

- Japanese language certification is an added advantage

- [Job Overview]:

- 5+ years of full-time experience in SAP PP

- General business process knowledge in SD , MM & CO.

- Integration knowledge with S/4HANA using SAP BTP-CPI & APIM

[Primary Skills]

Minimum of 5 years of experience in a full cycle implementation as well as in support projects.

- Module: PP

- Within the PP area, knowledge of manufacturing master is particularly necessary. Knowledge of manufacturing system master such as Material, BOM, Routing, and manufacturing version is preferable.

- Knowledge of BTP and SAP API integration is preferred.

- Modules: PP, CO, MM

- Knowledge of CO and MM as well as PP area is required.

- Knowledge of manufacturing system masters such as Material, BOM, Routing, and Manufacturing Version is recommended.

- In addition, understanding of transactions starting from the production order master, such as manufacturing results posting, receipt/issue processing, and batch master creation, is essential.

- In addition, an understanding of the integration with the CO area of cost accounting that is processed subsequently is also a good asset.

- Module: PP (CO)

- As a manufacturing master, knowledge of Routing is essential. However, since there are table references/updates for Material, BOM, and Routing in the RBP/RUT process, a comprehensive understanding of manufacturing system masters is required.

- Knowledge of CO area costing is also a better option.

[Good to have skills]

REST-API building and modification skills.Data is retrieved via REST-API for integration with MES. Knowledge of building general APIs and experience in API operation and maintenance is desirable

#######

Designs, develops, and supports solutions and processes to meet business needs and requirements.

Gathers and analyses business requirements for responsible work process.

Works closely with business process teams, technical teams and other stakeholders to design and build solutions which meet requirements.

Documents detailed designs.

Builds, tests and implements solutions.

Assists with issue resolution. Helps ensure that designs meet business requirements, conform to Dow architecture standards, and optimize application portfolio and long-term product/system vision.

Project Activities

- Interface with Project leadership and customers/clients to effectively complete implementation deliverables. Facilitating client involvement on deliverables where there is shared responsibility between the client and implementation project.

- Provide data analytics required for responsible work process.

- Lead and influence project team discussions, decisions, and direction for responsible work process.

- Help manage cross-functional implementation issues and interdependencies for Finance and ISC Finance process.

- Complete the as-is assessments of business processes, business organization, application portfolio, systems and infrastructure for responsible area.

- Review project requirements against standard business process MET, capturing gaps where most typical process, systems and infrastructure are not expected to suffice for a solution. Highlight these to the Business Process Teams.

- Ensure successful technical and functional handover of deliverables to the other DSS teams.

- Work with the data leads to explain and identify scope of master data. Coordinate in the identification of end users involved in testing, requiring training, and requiring changes to security profiles.

- Participate on the development of the approach and plans for end user testing and coordinate the User Acceptance Testing with end users.

- Participate on the development of training plans, and deliver work process & systems delta training. Participate on the development of the implementation approach, strategy and detailed plans.

- Participate on the development of cutover plans and approach.

- Gather input and develop the cutover check lists for responsible work process. Assists with the coordination and execution of implementation plans for data readiness, training, testing and cutover by facilitating the completion of tasks against the Implementation checklist.

- Provide post implementation support following production implementations. Facilitate the closure of defects or act as a liaison for end users to gain closure for defect. Facilitate issue resolution across DSS teams when needed.

- Facilitate handover to run-the-business operations.

Qualifications: –

- Experience with SAP ECC with a focus in PP configuration and processes

- Relevant working experience in any of these areas – APO, OMP, SAP PP/MM Module

- Minimum bachelor’s degree required in Computer science, Supply Chain, or relevant majors .

- A minimum of 7 years of relevant experience

- General knowledge of Information Technology work process, methodologies, and tools

- Effective communication in both oral and written English.

Preferred Skills: –

- Process knowledge with Integrated supply chain

- Strong analytical and problem-solving skills, reporting and Analytics knowledge.

- Ability to manage multiple initiatives and prioritize/manage workload

- Ability to lead and resolve complex problem situations and technical issues

- Ability to learn new processes and tools quickly

- Project Management or Change Management experience.

- Influencing people experience.

Benefits – What Dow Offers You

We invest in you.

Dow invests in total rewards programs to help you manage all aspects of you: your pay, your health, your life, your future, and your career. You bring your background, talent and perspective to work every day. Dow rewards that commitment by investing in your total wellbeing.

Here are just a few highlights of what you would be offered as a Dow employee:

- Equitable and market-competitive base pay and bonus opportunity across our global markets, along with locally relevant incentives.

- Benefits and programs to support your physical, mental and emotional well-being, to help you get the care you need…when you need it.

- Competitive retirement program that may include company-provided benefits, savings opportunities, financial planning and educational resources to help you achieve your long term financial-goals.

- Become a Dow shareholder through various employee stock programs.

- Opportunities to learn and grow through training and mentoring, work experiences, community involvement and team building.

- Workplace culture empowering role-based flexibility to maximize personal productivity and balance personal needs.

- Global Paid Time Off (PTO) policies:

- Paid time off for new parents (birthing and non-birthing, including adoptive and foster parents).

- Paid time off to care for family members who are sick or injured.

- Paid time off to support volunteering and Employee Resource Group’s (ERG) participation.

Join our team, we can make a difference together.

About Dow Chemical International Pvt Ltd

Dow Chemical International Private Limited (Dow India) aims to be the most innovative, sustainable, inclusive customer-centric materials science company. The company is committed to delivering the right solutions to its customers’ challenges. With broadest technology sets spanning performance materials, industrial intermediates, and plastics Dow India delivers differentiated science-based products and solutions in high-growth segments, such as packaging, infrastructure, automobile, and consumer care.

A Great Place to Work® Certified company with approximately over 1000 employees, its operations comprise of manufacturing sites, innovation center, established centers of excellence, and commercial office. As a responsible corporate, the company supports its Corporate Social Responsibility (program) with technology expertise and employee volunteerism. Dow India works with non-profit partners towards the empowerment of differently abled, women, and children in communities where it operates. The company aims to redefine the societal blueprint, by supporting holistic sustainability and circular economy initiatives.